Every year in the U.S., about 1.3 million medication errors happen in hospitals and pharmacies. Many of these mistakes could be stopped before they reach a patient - and barcode scanning is one of the most effective tools doing exactly that.

Picture this: a pharmacist pulls a vial of insulin from the shelf. The label says "100 units/mL". The prescription calls for 10 units. Without a barcode scanner, the pharmacist relies on eyesight, memory, and a second check. But what if the label is smudged? What if the wrong vial was placed in the wrong bin? What if the pharmacist is tired, distracted, or rushing? This is where barcode scanning changes everything.

Barcode scanning in pharmacies isn’t just a tech upgrade. It’s a safety net. It checks the five rights: right patient, right medication, right dose, right route, right time. And it does this in seconds - before the pill ever leaves the counter.

How Barcode Scanning Stops Errors Before They Happen

Modern pharmacy barcode systems work by scanning two things: the patient’s wristband and the medication’s barcode. The system doesn’t just read the numbers - it compares them against the electronic prescription in real time.

Here’s how it works step by step:

- The pharmacist selects the medication based on the prescription.

- They scan the patient’s wristband - which contains the patient’s name, medical record number, and allergies.

- They scan the barcode on the medication package - which contains the National Drug Code (NDC), strength, quantity, and lot number.

- The system instantly checks: Does this medication match what was ordered for this patient? Is the dose correct? Is the patient allergic to this drug?

- If everything matches, the system approves the dispense. If there’s a mismatch - say, the wrong drug or a 10x overdose - the system stops the process and alerts the pharmacist.

This isn’t theory. A 2021 study in BMJ Quality & Safety found that when barcode systems are used correctly, they prevent 93.4% of potential dispensing errors. That’s not close. That’s nearly universal protection.

One Pennsylvania hospital tracked actual errors before and after installing barcode scanners. Before: 13.5% of medications were given incorrectly. After: just 3%. That’s a 75% drop in mistakes.

The NDC Barcode: The Backbone of Safety

The magic behind this system? The National Drug Code (NDC). This is a 10-digit number assigned by the FDA to every prescription and over-the-counter drug in the U.S. It’s unique to each product - manufacturer, strength, dosage form, and package size.

Since 2006, the FDA has required every unit-dose package - whether it’s a blister pack, bottle, or vial - to carry the NDC in barcode format. That means every pill, capsule, or injection has a digital fingerprint.

Before this rule, pharmacists had to rely on visual matching. "Is this amoxicillin 500mg or 875mg?" "Is this lorazepam 0.5mg or 2mg?" The labels look almost identical. A tiny mistake can kill.

With barcode scanning, the system doesn’t care how similar they look. It reads the code. And if the code says "0.5mg" but the order says "2mg" - it flags it. No guesswork.

Why Manual Checks Don’t Cut It

You might think: "Why not just have two pharmacists check each prescription?" It sounds safe. But studies show manual double-checks catch only about 36% of errors.

Why so low? Because humans are bad at repetitive verification. If you’ve checked 50 prescriptions in a row, your brain starts to auto-pilot. You see what you expect to see. You miss the outlier.

Barcodes don’t get tired. They don’t assume. They don’t skip steps. They scan. They compare. They alert.

And the numbers back it up. A 2022 report from the Agency for Healthcare Research and Quality (AHRQ) found that barcode systems prevent:

- 89% of wrong-drug errors

- 86% of wrong-dose errors

- 92% of wrong-patient errors

Compare that to manual checks - which miss 64% of these mistakes. The difference isn’t marginal. It’s life-or-death.

What Happens When the Barcode Doesn’t Scan?

Barcodes aren’t perfect. And that’s where many systems fail.

Some medications - like insulin pens, ampules, or compounded drugs - have tiny, fragile, or damaged labels. A 2024 ECRI Institute report found that 15% of all scanning attempts fail because the barcode is smudged, torn, or covered in condensation.

Here’s the dangerous part: when the scanner beeps red, some pharmacists just slap on a new label and scan that instead. They don’t look at the actual drug. They don’t check the vial. They trust the system.

That’s automation bias. And it’s deadly.

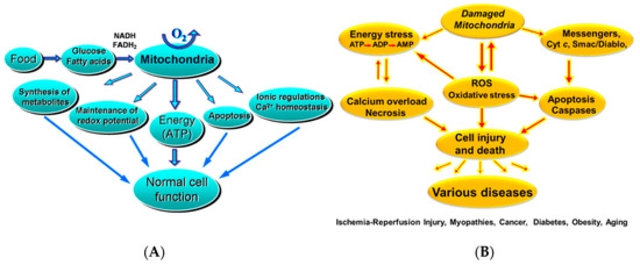

One case from the Pennsylvania Patient Safety Authority tells the story: a pharmacy staff member accidentally labeled a vial of vancomycin with the wrong concentration - 10mg/mL instead of 50mg/mL. But the barcode was correct. The scanner approved it. The nurse administered it. The patient suffered kidney failure.

The lesson? Never scan and assume. If the barcode won’t scan, you must visually verify the medication against the prescription. Always. No exceptions.

Real-World Challenges Pharmacists Face

Most pharmacists agree: barcode scanning saves lives. But it’s not without friction.

On the ASHP Community Forum, pharmacist Sarah Chen says: "We’ve cut our errors by 75%, but scanning ampules is a nightmare. The labels are too small. We need special trays and perfect lighting. Otherwise, we’re stuck waiting for the scanner to catch up."

Reddit user u/HospitalPharmTech shared: "It adds 15-20 minutes to every shift. We’re constantly fixing scanner jams, re-scanning vials, and dealing with system freezes during rush hour. Sometimes, we just skip the scan - we’re too busy to wait."

A 2023 survey of 1,247 pharmacists found:

- 78% saw fewer errors after implementation

- 63% said workflow was disrupted

- 41% admitted to bypassing scans during emergencies

- 52% felt undertrained on how to handle scanning failures

These aren’t complaints. They’re red flags.

When staff bypass scanners, error rates creep back up. When training is weak, workarounds become habits. When systems freeze, safety becomes a luxury.

What Works: Best Practices from Leading Pharmacies

High-performing pharmacies don’t just install scanners. They redesign their whole process around them.

Here’s what works:

- Scan manufacturer barcodes - not pharmacy labels. Pharmacy-applied labels can be wrong. Manufacturer labels are printed with the product and can’t be altered. Always scan the original.

- Use special trays for small vials. Insulin pens, ampules, and inhalers need stable, well-lit scanning surfaces. Dedicated trays reduce scanning failures by 40%.

- Review scanning data weekly. Which drugs are most often scanned incorrectly? Which barcodes fail most? Track it. Fix it.

- Train staff on escalation. If a barcode won’t scan, there’s a protocol: stop, verify visually, document the issue, report it to the pharmacy manager. No shortcuts.

- Test new products before they hit the shelf. ECRI recommends that pharmacies scan every new medication before accepting delivery. If the barcode doesn’t read, reject the shipment.

These aren’t optional. They’re the difference between a system that works - and one that just looks good.

Barcodes vs. New Tech: Why Barcode Scanning Still Wins

RFID tags? Smart pumps? AI-powered drug recognition? They’re coming. But right now, barcode scanning is still the gold standard.

RFID tags can store more data - but they cost 47% more per unit. Smart pumps prevent IV errors - but they don’t help with oral meds. AI recognition is still experimental.

Barcode scanning works with existing pharmacy systems. It’s proven. It’s affordable. And it’s mandated.

Adoption rates tell the story: 78% of U.S. hospitals use barcode systems. In community pharmacies? Only 35%. Why? Cost. Training. Infrastructure.

But for hospitals with 300+ beds? 92% use it. Because they’ve seen the data. Because they’ve seen the lives saved.

What’s Next? The Future of Barcode Safety

The FDA is testing 2D barcodes - matrix codes that can store lot numbers, expiration dates, and even batch-specific safety alerts. By 2026, the American Society of Health-System Pharmacists predicts 65% of medications will use 2D barcodes - up from just 22% in 2023.

Some vendors are adding AI. Epic Systems’ 2024 update improved scanning success by 22% using mobile-integrated scanners. Cerner plans AI-assisted barcode recognition in 2025 - predicting when a label might fail before it even gets scanned.

But the core won’t change: technology doesn’t prevent errors - people using technology correctly do.

The best barcode system in the world won’t stop a mistake if the pharmacist ignores the alert. The most advanced scanner won’t help if the label is printed wrong.

That’s why training, culture, and accountability matter more than ever.

Final Thought: It’s Not About the Scanner - It’s About the Process

Barcode scanning isn’t magic. It’s a tool. A powerful one. But tools are only as good as the hands that use them.

When used right, barcode scanning prevents 9 out of 10 medication errors. It stops overdoses before they happen. It catches wrong drugs before they leave the counter. It protects patients who can’t protect themselves.

But when it’s ignored, bypassed, or poorly managed - it becomes a false sense of security.

The goal isn’t to scan everything. The goal is to ensure that every medication goes to the right person, in the right dose, at the right time. And barcode scanning - done right - is the most reliable way we have to make that happen.